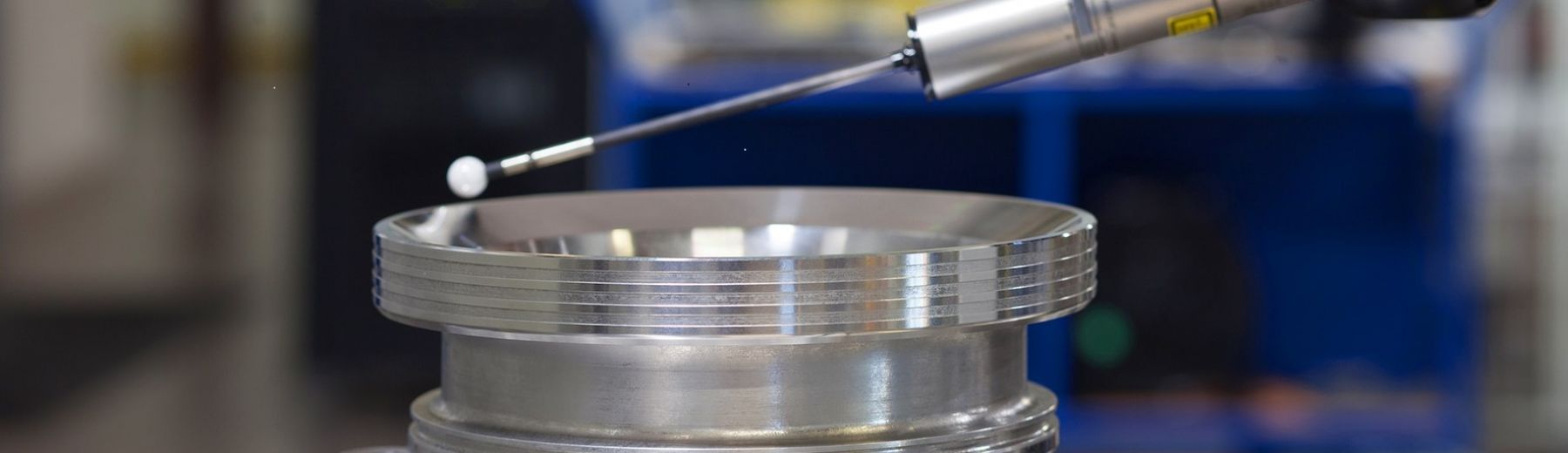

Valve seats

First-class components of the combustion chamber

Highest requirements for large engines

The medium speed four-stroke diesel engine sector includes cylinder output of up to 2,150 kilowatts, with cylinder bores as large as 640 millimetres. Our clients receive one-stop comprehensive quality: M. JÜRGENSEN carries out all process steps through to the ready-to-install component. Our machinery is precisely tuned to the diversity of this specialised market.

Flexible production processes from centrifugal casting up to the ready-to-install product allow us to reliably meet our customers’ specifications – including materials which are hard to be machined.

It is a matter of course for M. JÜRGENSEN to keep adjusting to reflect dynamic developments in the market. This is true not only for technical equipment but also with regard to our manufacturing capacity. Customers value us as an expert development partner and a flexible, loyal supplier.

We produce valve seats in cooperation with our associate company Kuhn Special Steel. The internal diameters for valve seats start at about 30 mm and cover the entire range of four-stroke large bore engines. Our valve seat rings used in high temperature applications are exposed to a combination of abrasive and corrosive wear, which is why special alloys produced by us are used here. The materials vary from high-alloy grey cast iron products to pure, iron-free chromium-nickel or cobaltbased alloys. Thanks to the centrifugal casting technique, we can guarantee the greatest purity and an optimal structure that cannot be achieved with any other casting technique.

We would be pleased to answer your questions about centrifugal casting and the application spectrum for engine and machine components. Our customer support starts with the design phase, continued by prototypes which are followed by serial production. Finally, we stay in touch with our excellent after-sales service.

Just call us on:

+49 (0)4635 299-0

salesnothing@m-juergensen.de